In the pharmaceutical industry, water is not just a basic necessity — it is a critical raw material. Whether used for manufacturing, cleaning, or as an ingredient in formulations, water quality directly impacts product safety and effectiveness. G. T. Metals and Tubes, a trusted name in precision-engineered storage solutions, is playing a vital role in supporting the Water System in Pharmaceutical Industry through their advanced range of water storage containers and purified water storage tanks.

The Crucial Role of Water in Pharma

Pharmaceutical operations rely on different grades of water such as Purified Water (PW), Water for Injection (WFI), and Sterile Water, depending on the process. These water types must meet stringent quality standards and remain free from microbial and chemical contamination throughout storage and distribution. Any compromise in water quality can lead to regulatory issues, product recalls, or even public health risks.

Challenges in Water Storage and Distribution

Maintaining the purity of water during storage is one of the most complex challenges in pharmaceutical water systems. Stainless steel tanks that are not properly designed can harbor microbial growth, leach contaminants, or fail to support proper cleaning processes. To overcome these challenges, pharmaceutical companies require storage systems that are hygienically designed, corrosion-resistant, easy to sterilize, and built to withstand rigorous operational conditions.

G. T. Metals and Tubes: A Trusted Partner

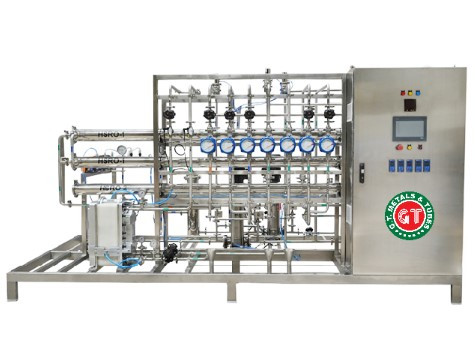

G. T. Metals and Tubes specializes in manufacturing premium-grade water storage containers and purified water storage tanks that meet global pharmaceutical standards. Their tanks are crafted from high-grade stainless steel (such as SS316L) known for its resistance to corrosion and chemical reactions. Each unit is designed with a focus on sanitary construction, ensuring smooth surfaces, crevice-free joints, and clean-in-place (CIP) compatibility.

Their storage systems are ideal for both static and dynamic storage of Purified Water and WFI. The tanks come with features such as air vent filters, spray balls for cleaning, diaphragm valves, and thermal insulation. These ensure not only the physical safety of the water but also the ease of validation and compliance with cGMP and FDA norms.

Applications Beyond Pharma

While their core expertise lies in supporting the water system in the pharmaceutical industry, G. T. Metals and Tubes also caters to biotech, cosmetic, food and beverage, and chemical sectors — all of which demand equally high water storage standards.

Customization and Quality Assurance

Understanding that no two facilities are the same, G. T. Metals and Tubes offers fully customizable solutions. From tank capacity and mounting options to integration with automation systems, every product is designed to align with client-specific operational needs. All tanks are subjected to rigorous quality checks, including hydrostatic testing, surface finish inspection, and weld integrity testing.

Conclusion

In an industry where product integrity hinges on the smallest variables, the quality of water storage systems cannot be overlooked. G. T. Metals and Tubes has positioned itself as a reliable provider of high-performance purified water storage tanks and water storage containers — enabling pharmaceutical manufacturers to uphold safety, consistency, and regulatory compliance. By investing in their solutions, pharma companies ensure the heart of their water system remains pure, reliable, and efficient.